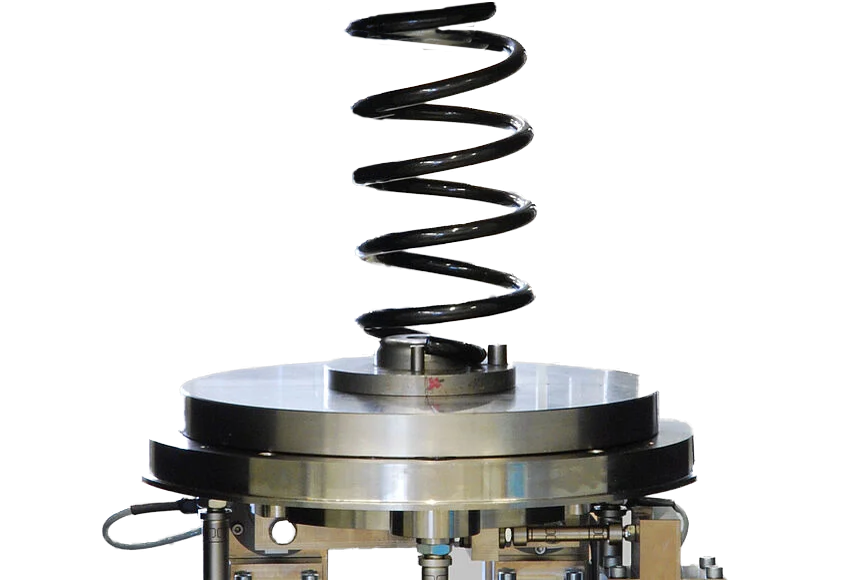

Jackson Spring is the choice for custom springs and wire forms. From compression springs, extension springs, to torsions springs and wire forms, we have the ability to produce a variety of springs to suit your needs.

We have experienced design personnel and an extensive library of computerized design programs. Whether you require a design to eliminate a problem, reduce cost, or a new design for a new product, we will promptly provide you with the information you need.

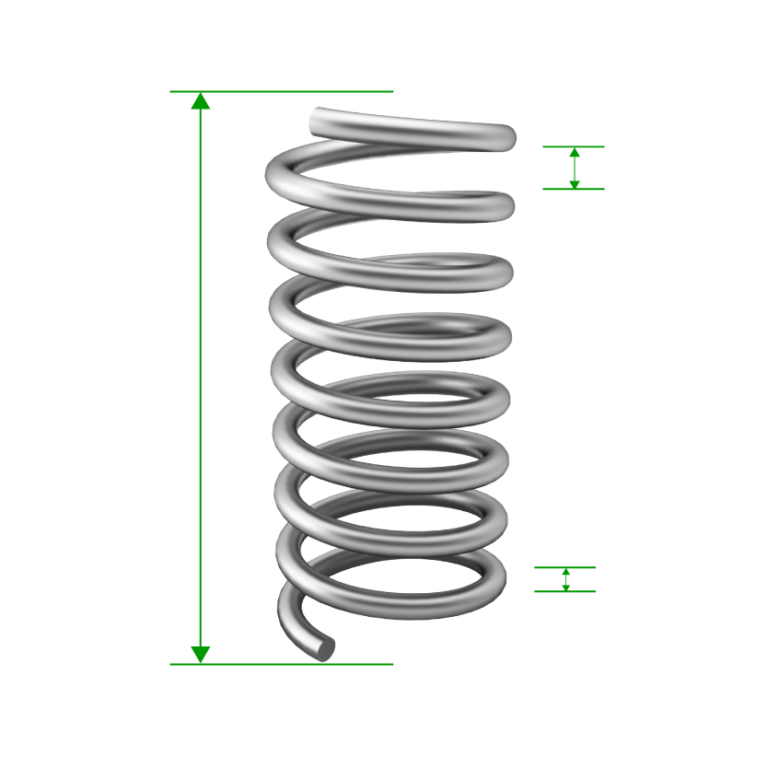

We take special pride in our ability to manufacture parts having stringent load or squareness requirements. By using sophisticated manufacturing methods we can produce parts having very tight tolerances, both accurately and economically.

On-going training programs, a team approach to problem solving, and continual direct employee involvement in day to day operations all serve to promote a culture that promotes manufacturing excellence.

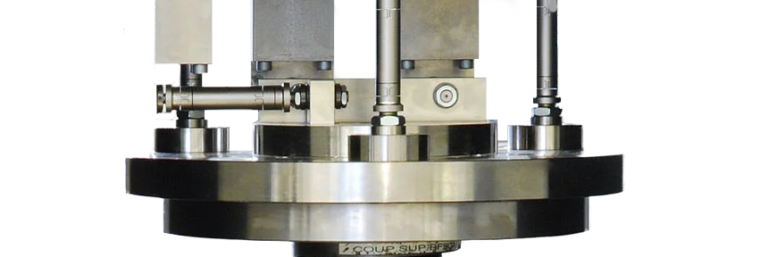

With the use of multi-axis CNC machines, we have the ability to produce complex parts completely off of the machine, eliminating the need for costly secondary operations. We also have a full grinding department and access to a variety of finishes.